Common 3D Printing Mistakes and How to Avoid Them

Learn from others' mistakes: the most common 3D printing problems and how to prevent them. From warping to layer adhesion - practical solutions explained.

Dennis

3Dennis

Contents

Everyone who works with 3D printing encounters problems. Failed prints, quality issues, mysterious defects - it’s part of the learning process. But many problems are predictable and preventable.

At 3Dennis, we’ve seen thousands of prints pass through. Here are the most common mistakes and how to avoid them.

Mistake 1: Skipping bed leveling

A level print bed is the foundation for every successful print. Too close, and the first layer gets squeezed flat or doesn’t come out at all. Too far, and the filament doesn’t stick.

The symptoms

- First layer doesn’t stick

- Filament rolls into balls instead of lines

- One corner lifts while another is stuck

- Inconsistent first layer thickness

The solution

Level your bed before every print session, or at least check it. Use the paper test: a sheet of paper should slide under the nozzle with slight resistance. Better yet, use an automatic bed leveling sensor if your printer supports it.

Also check if your bed is actually flat. Some beds have a slight curve, requiring compensation in the center.

Mistake 2: Wrong temperature settings

Every filament has an optimal temperature range. Too hot causes stringing and blobs. Too cold results in poor layer adhesion and weak prints.

The symptoms

- Strings between parts of the print

- Blobs and zits on the surface

- Layers that separate easily

- Print that looks “rough” or uneven

The solution

Start with the temperature recommended by the filament manufacturer. Then fine-tune based on results. Print a temperature tower to find the sweet spot for your specific combination of filament and printer.

Remember: ambient temperature matters too. A cold room requires different settings than a warm one.

Mistake 3: Printing too fast

Speed is tempting, but pushing your printer too hard leads to quality problems. The printer can’t keep up with extruding enough material, the motion system introduces vibrations, and details get lost.

The symptoms

- Visible “ringing” or ghosting around corners

- Inconsistent layer lines

- Under-extrusion (gaps in walls)

- Loss of fine details

The solution

Slow down. The time savings from high speed often aren’t worth the quality loss. For visible parts, 50-60mm/s is often better than 100mm/s, even if your printer can handle it mechanically.

If you need speed, invest in a printer designed for it. Modern high-flow printers can print fast while maintaining quality.

Mistake 4: Ignoring support settings

Overhangs beyond 45 degrees need support. Ignoring this results in failed prints or horrible quality on overhang surfaces.

The symptoms

- Droopy or stringy overhangs

- Failed prints when overhangs completely collapse

- Rough surfaces where support should have been

The solution

Use supports where needed. Yes, they cost material and need removal, but they’re necessary for certain geometries.

Better yet: design parts with 3D printing in mind. Chamfers instead of overhangs, orientation that minimizes supports, splitting complex parts into simpler components.

Mistake 5: Wrong material for the application

PLA is easy to print but has limitations. Using it for outdoor applications, high temperatures, or mechanical stress is asking for failure.

The symptoms

- Parts that warp or deform over time

- Brittle failures under load

- Degradation from UV or moisture

The solution

Choose the right material for your application:

- PLA: Indoor decorative items, prototypes

- PETG: Functional parts, outdoor use, food contact

- ABS/ASA: High temperature, automotive

- Nylon: Mechanical wear, flexibility

At 3Dennis, we primarily use PETG because it offers the best balance of printability and performance for most applications.

Mistake 6: Insufficient cooling

Proper cooling is crucial for print quality, especially for overhangs and small features. Too little cooling and the plastic doesn’t solidify fast enough.

The symptoms

- Overhangs that droop even at reasonable angles

- Small features that deform or “melt”

- Poor quality on bridges

- Curling layers

The solution

Ensure your part cooling fan is working properly and pointing at the right spot. For PLA and PETG, run the fan at 100% for most of the print.

Note: the first few layers should have reduced or no cooling to ensure bed adhesion. Most slicers handle this automatically.

Mistake 7: Neglecting printer maintenance

Printers need maintenance. Worn nozzles, dirty rods, loose belts - these all cause print quality issues that are hard to diagnose.

The symptoms

- Gradual quality degradation

- Inconsistent extrusion

- Print dimensions drifting

- Strange noises

The solution

Schedule regular maintenance:

- Clean the bed before each print

- Check belt tension weekly

- Lubricate rods monthly

- Replace nozzles after 500-1000 print hours

- Clean the extruder gears periodically

A well-maintained printer gives consistent results. Neglect leads to mysterious problems.

Mistake 8: Wrong first layer speed

The first layer is crucial. Printing it too fast prevents proper adhesion. This single setting affects whether your print succeeds or fails.

The symptoms

- First layer peeling off during print

- Poor adhesion on one side

- Warping that starts from the corners

The solution

Print the first layer slowly - 20-30mm/s maximum. Give the plastic time to bond with the bed. Also use a slightly higher temperature for the first layer to improve flow.

Learning from mistakes

The best way to avoid mistakes is to understand why they happen. Every failed print teaches something. Keep notes on what went wrong and what fixed it.

At 3Dennis, we’ve learned from thousands of prints. When you order from us, you get the benefit of that experience. We know what works and what doesn’t, so your parts come out right the first time.

Need help with a tricky print? Contact us and we’ll solve it together.

Keep reading

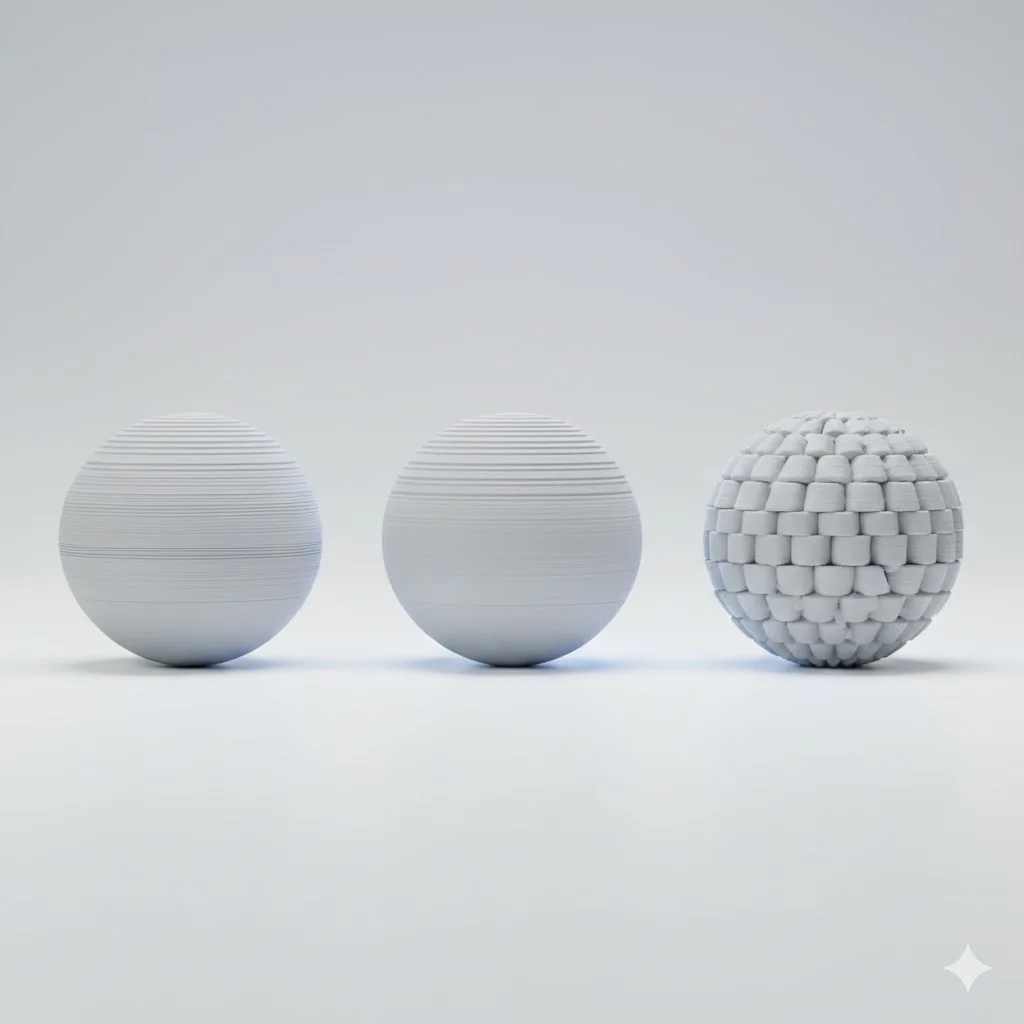

Layer Height in 3D Printing: The Trade-off Between Quality and Speed

What's the best layer height for your 3D print? Learn how layer height affects quality, strength, and print time. Practical guidelines for every application.

Choosing the Right Infill Percentage: A Complete Guide

How much infill does your 3D print really need? Learn when to use 20%, 50%, or 100% infill for optimal strength, weight, and print time.

Designing for 3D Printing: Professional Tips

Learn how to design parts that are perfectly 3D printable. From wall thickness to overhangs - the most important design rules for successful prints explained.

Need help with your project?

Contact us for custom 3D prints or B2B services.