Custom Enclosures: 3D Printing vs Injection Molding - The Honest Comparison

When do you choose 3D printed enclosures and when injection molding? A practical comparison of costs, lead times, and quality for businesses.

Dennis

3Dennis

Contents

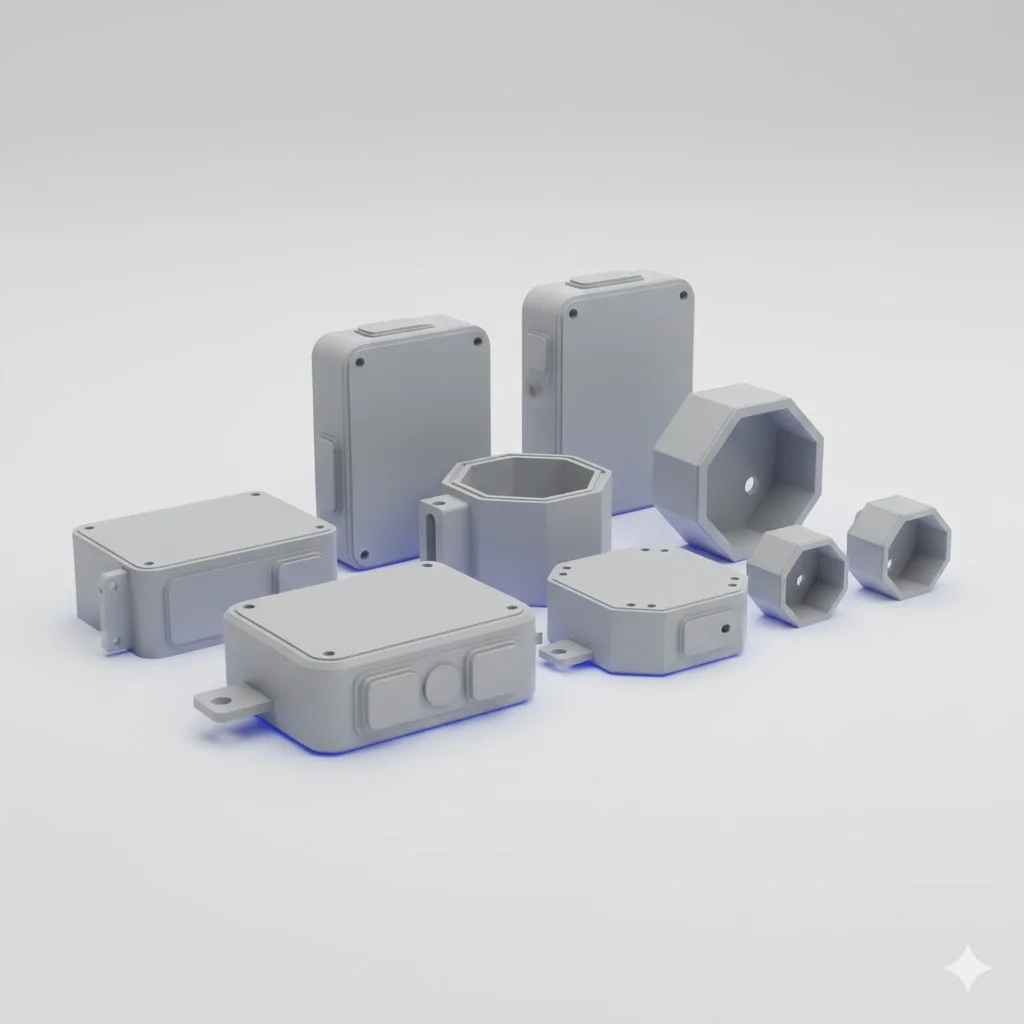

You need an enclosure for your product. Electronics, sensors, mechanical parts - everything needs a shell that protects, functions, and looks good. The big question: do you have it 3D printed or invest in injection molding?

The answer depends on your volume, timeline, and budget. In this article, we put both options honestly side by side, so you can make the best choice for your situation.

The fundamental differences

Injection molding: mass production king

With injection molding, molten plastic is pressed into a metal mold under high pressure. The mold is a precision instrument, often CNC milled from steel or aluminum, that exactly determines your enclosure’s shape.

Advantages:

- Extremely low unit price at high volumes

- Perfect reproducibility

- Wide material selection including engineering plastics

- Smooth surface directly from the mold

Disadvantages:

- Mold costs €5,000 - €50,000+

- Mold lead time 4-12 weeks

- Design changes require new mold

- Minimum order volumes

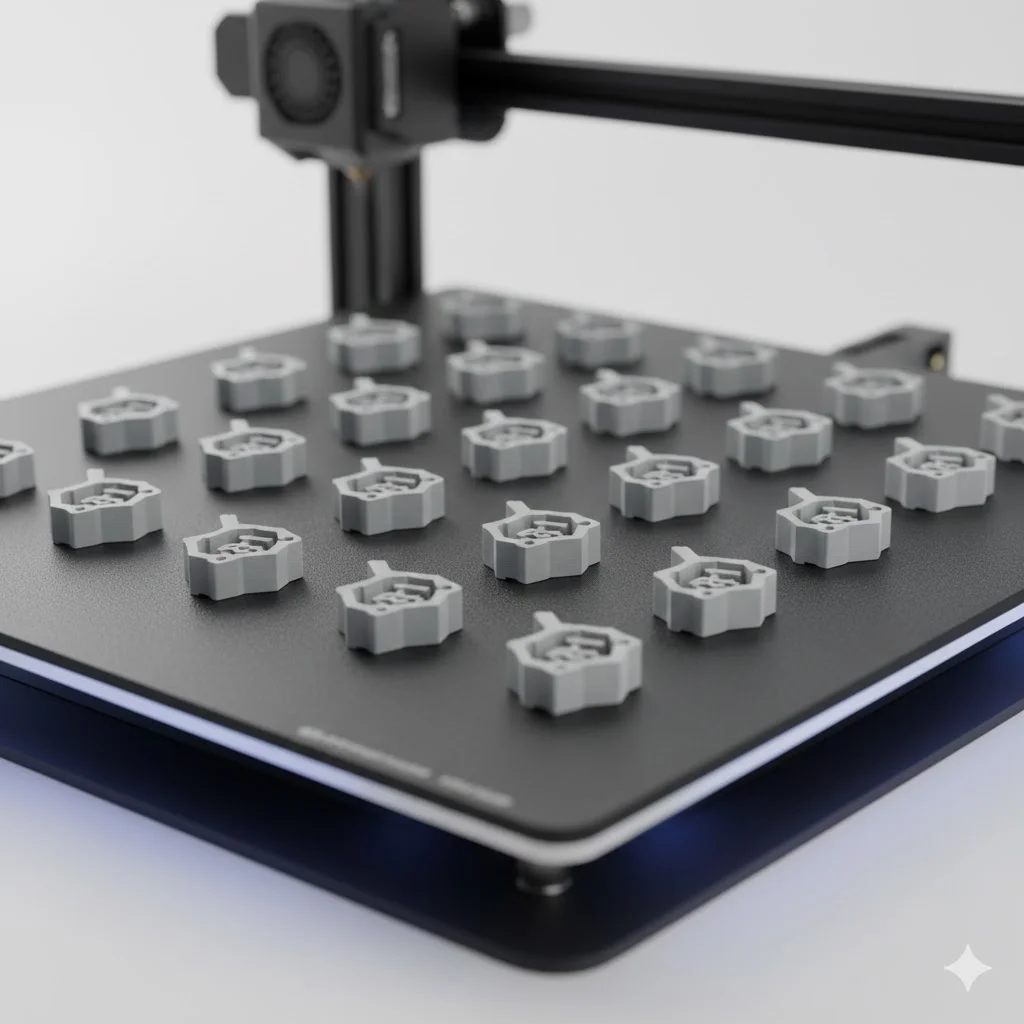

3D Printing: flexibility trumps all

With 3D printing, the enclosure is built layer by layer from filament or resin. No tooling needed - the CAD file is directly the production instruction.

Advantages:

- No tooling costs

- Lead time in days

- Changes immediately implementable

- No minimum volumes

- Complex geometry possible

Disadvantages:

- Higher unit price at volume

- Visible layer lines (depending on technology)

- More limited material selection

- Longer production time per piece

The cost crossover: where’s the tipping point?

The crucial question is: at what volume does injection molding become more economical than 3D printing? This varies by part, but we can make a realistic estimate.

Example calculation: simple enclosure

Take an enclosure of 10×10×5 cm, relatively simple design.

3D printing (PETG):

- Material costs: €8 per piece

- Print time costs: €12 per piece

- Post-processing: €2 per piece

- Total: €22 per piece

Injection molding:

- Mold costs: €8,000 (one-time)

- Production costs: €1.50 per piece

At these numbers, the crossover point is:

- €8,000 / (€22 - €1.50) = 390 pieces

Under 390 pieces, 3D printing is cheaper. Above that, injection molding wins.

Example calculation: complex enclosure

Now an enclosure with internal ribs, snap-fits, and multiple openings.

3D printing:

- Complexity increases print time: €35 per piece

Injection molding:

- More complex mold: €18,000

- Production costs: €2 per piece

Crossover point: €18,000 / (€35 - €2) = 545 pieces

Complexity shifts the crossover point because mold costs rise more than 3D printing costs.

But cost isn’t everything

Time-to-market

In competitive markets, speed is often more important than the lowest unit price. If you can be on the market three months earlier, that can be worth more than production cost savings.

Scenario: Your competitor launches a similar product. With 3D printing, you can produce and sell 200 pieces within two weeks. With injection molding, you wait three months for the mold.

Those three months of market lead - or lag - is hard to express in euros, but can be decisive for success.

Iteration and improvement

Products evolve. Customer feedback, technical improvements, cost optimization - there are countless reasons to adjust a design.

With 3D printing: modify the CAD file, print the next batch with improvements.

With injection molding: order a new mold or have the existing one modified. Cost: thousands of euros. Lead time: weeks.

This makes 3D printing ideal for products still in development, even if final volumes will be large.

Complexity costs nothing extra

With injection molding, complexity significantly increases mold costs. Undercuts require sliders in the mold, thin walls are hard to fill, and internal structures are often impossible.

With 3D printing, complexity is free. Internal channels, organic shapes, integrated hinges - it all prints without extra cost. This opens design possibilities that simply don’t exist with injection molding.

Hybrid strategies

The smartest businesses don’t dogmatically choose one method, but combine the best of both worlds.

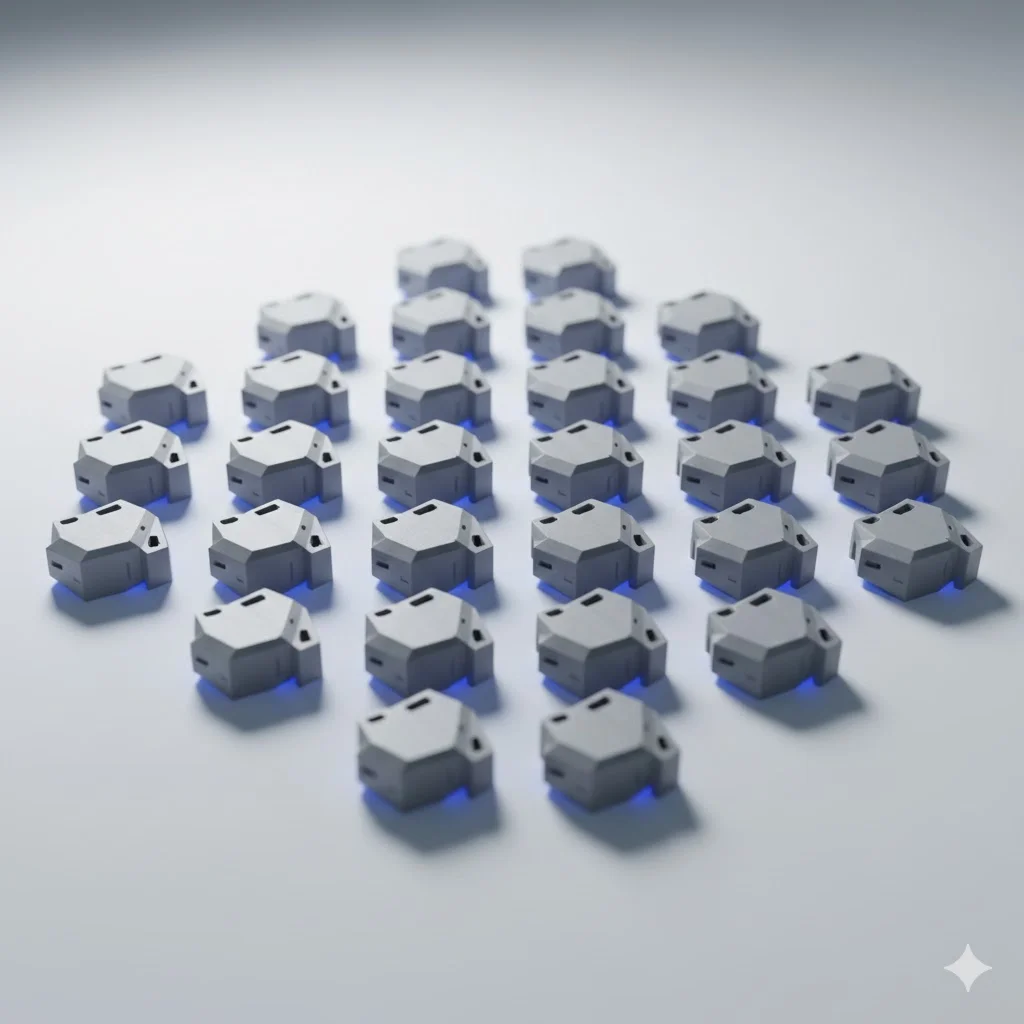

Bridge production

Start with 3D printed enclosures during product development and early sales. Use this period to:

- Refine the design based on real feedback

- Validate market demand

- Generate capital for the mold investment

When the design is stable and volumes justify it, invest in injection molding. The 3D printed version serves as exact reference for the mold.

Differentiation by variant

Maybe you have one base model going in large volumes, and ten variants for specific customers or applications.

Injection mold the base model. 3D print the variants. You get scale cost advantages where you can, and customization flexibility where needed.

Geographic distribution

Some companies injection mold in Asia for low costs, but keep 3D printing capacity local for quick deliveries and rush orders. The best of both worlds.

Quality comparison

Surface quality

Injection molding wins on surface quality. A good mold produces enclosures with perfectly smooth surfaces, sharp details, and consistent finish.

3D printed parts show layer lines, especially on curved surfaces. With post-processing (sanding, coating) much is possible, but it costs extra time and money.

For consumer products where appearance is critical, this can be a decisive argument for injection molding. For B2B applications or internal parts, it rarely matters.

Mechanical properties

Injection molded parts are isotropic - equally strong in all directions. 3D printed parts are stronger in the layer plane than perpendicular to it.

For critical mechanical applications, this is a consideration. In practice, it’s rarely a problem for enclosures - they don’t carry heavy loads.

Dimensional accuracy

Both methods can achieve tight tolerances. Injection molding is more consistent across large quantities. 3D printing may show slight variation between prints, though with good process control this is minimal.

Our recommendation

After years of experience with both methods, our advice:

Choose 3D printing when:

- You need fewer than 500-1000 pieces

- The product is still in development

- Time-to-market is critical

- You need multiple variants

- The design contains complex geometry

Choose injection molding when:

- Your volumes exceed 1000 pieces

- The design is stable and validated

- Surface quality is essential

- You need the same version for years

Combine both when:

- You want to start selling while scaling

- You have a base model and variants

- You want to maintain flexibility for the future

Getting started

Wondering which approach best fits your enclosure project? We’re happy to help. Send your design and volumes, and we’ll make an honest comparison with concrete numbers for your situation.

At 3Dennis, we’re not an injection molding company, so we have no interest in selling molds. We advise objectively on what works best for you - even if that’s injection molding.

Contact us for a no-obligation consultation.

Keep reading

B2B 3D Printing: How Businesses Save Time and Money with Custom Parts

Discover how businesses save costs with 3D printed parts. From prototypes to production runs - the business benefits of 3D printing explained.

Fast Lead Times: How 3D Printing Shortens Delivery Times

Waiting for parts costs money. Discover how 3D printing drastically reduces lead times - from weeks to days. Same-week delivery for businesses.

Batch 3D Printing for Businesses: Producing Small Runs Efficiently

How does batch 3D printing work? Discover the advantages of series production with 3D printing for businesses. From 10 to 1000 pieces - efficient and affordable.

Need help with your project?

Contact us for custom 3D prints or B2B services.